Manufacturing facilities are tailored environments optimized for specific production needs, focusing on workflow, real estate size, loading access, and utility availability. Flexible real estate solutions accommodate diverse operations, enhancing productivity and agility through specialized layouts. Strategic location considerations, including infrastructure, labor, zoning, and environmental impact, ensure successful and sustainable manufacturing hubs.

Manufacturing facilities aren’t one-size-fits-all. To thrive, they demand specialized features tailored to unique production needs. This article delves into three crucial aspects: understanding specific space requirements, integrating efficient layouts, and navigating real estate considerations for customized facilities. By exploring these elements, businesses can optimize their operations, enhance productivity, and stay competitive in today’s market. Explore the importance of personalized manufacturing spaces and unlock the potential for success through strategic real estate choices.

Understanding Unique Manufacturing Space Needs

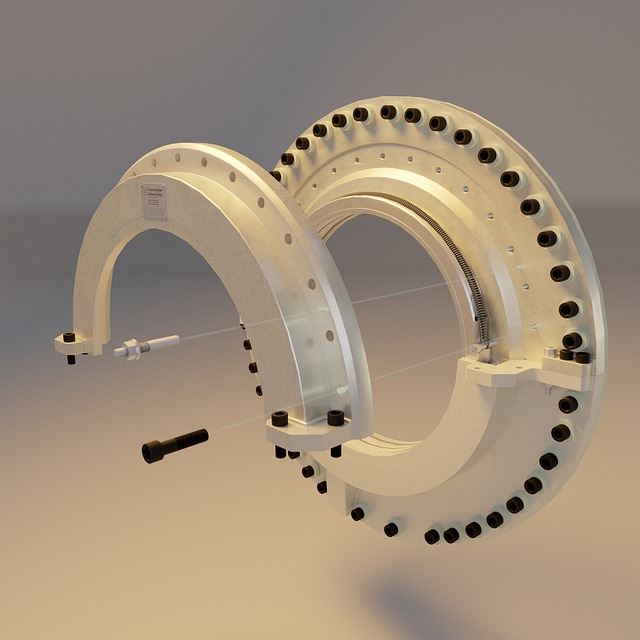

Manufacturing facilities are more than just buildings; they are tailored environments designed to meet specific production requirements. When it comes to understanding unique manufacturing space needs, several key factors must be considered. The first is workflow optimization. Each manufacturing process has its own set of steps and demands, requiring layout designs that facilitate efficient movement of materials and personnel. For instance, assembly lines need ample space for machines and workers, while storage facilities require shelving and racking systems to maximize vertical space.

Real Estate plays a pivotal role in accommodating these needs. The size and type of facility must align with production scale, equipment specifications, and inventory management strategies. Additionally, considerations such as loading docks, vehicle access, and utility availability are crucial. By meticulously addressing these aspects, manufacturers can create an optimized workspace that enhances productivity, reduces waste, and supports long-term operational goals.

Integrating Specialized Layouts for Efficiency

Manufacturing facilities are not one-size-fits-all operations, and their real estate needs should reflect this diversity. Integrating specialized layouts is a key strategy to enhance efficiency and productivity within these dynamic environments. By carefully designing spaces tailored to specific manufacturing processes, companies can optimize workflow and minimize bottlenecks. For instance, assembly lines require linear layouts for streamlined movement, while storage and distribution centers benefit from intricate, maze-like arrangements to maximize space utilization.

This approach not only improves overall operational effectiveness but also accommodates the ever-changing demands of modern manufacturing. Flexible and adaptable real estate solutions enable facilities to pivot between production runs, adapt to new product lines, or even switch manufacturing methods with minimal disruption. As such, investing in specialized layouts is a strategic move that pays dividends in terms of agility, cost-efficiency, and long-term sustainability for manufacturing operations.

Real Estate Considerations for Customized Facilities

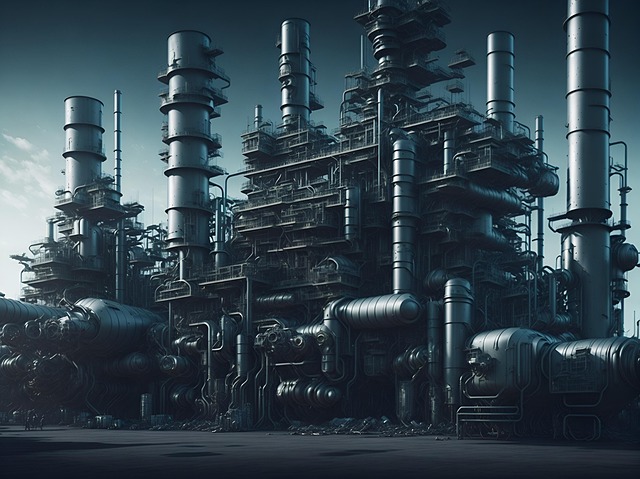

When designing and establishing manufacturing facilities, one often overlooked yet critical aspect is the real estate considerations. The choice of location plays a pivotal role in shaping the entire operation’s success and efficiency. Factories require ample space for machinery, storage, and workplace areas, necessitating a strategic approach to real estate selection.

In today’s competitive market, businesses must look beyond traditional industrial zones. Customized facilities often thrive in areas with specific infrastructure and logistical advantages. This might include proximity to transportation networks, availability of skilled labor, or access to raw materials. Real estate decisions should also consider zoning regulations, environmental impact, and the local community’s needs to ensure a sustainable and harmonious manufacturing hub.